Floor Joints

Filter Your Product

-

£3.44 - £50.71 ex. VATSoudal Soudaflex 40FC is a high-quality polyurethane sealant and adhesive perfect for a vast number of applications. It is ideal for bonding and sealing panels. It is also a high-quality joint sealant, being used in road and bridge building, as well as industrial flooring applications. Colours: White, Black and Concrete Grey - Sealant and adhesive - High modulus, polyurethane formula - Specifically formulated for concrete applications - Structural bonding of joints subject to vibration - Adheres to most common construction substrates - Chemical resistant - Durable, long-l

-

£8.25 - £159.03 ex. VATSikaFlex PRO-3 is a 1-component, elastic joint sealant with high mechanical and chemical resistance. Therefore, making it ideal for a wide range of construction applications. CHARACTERISTICS / ADVANTAGES - Movement capability of ± 35% - Very high mechanical and chemical resistance - Bubble-free curing - Good adhesion. Therefore making it ideal to use with most construction materials. - Solvent-free - Very low emissions Please note, PRO-3 Purform is a new formula introduced 2022 For application guns, click here, or for all other Sika products on

-

£8.25 ex. VATEverbuild Puraflex 40 is a high modulus, one component, PU sealant and adhesive which adheres strongly to most substrates. Provides excellent mechanical resistance & resistance to most common chemicals. Furthermore, this product can be over-painted when cured. Advantages - Bonds to wood, concrete, metal, aluminium, polyester, glass, uPVC, stone, ceramics, etc - Can be painted with gloss and emulsion. - Good sea water resistance. - Can be painted with oil and latex paints. - In addition to the above, if you require further information on this product, you can

-

£10.92 ex. VATSikaflex PRO-3 Purform Self Levelling is a one-part, moisture curing, self-levelling elastic joint sealant with high mechanical resistance for the following indoor and outdoor applications: Characteristics / Advantages ■ Movement capability of 25% (ISO 9047) ■ Bubble-free curing ■ Self-levelling ■ Excellent adhesion to most construction materials ■ Solvent-free and odourless ■ Very low emission Please note, PRO-3 Purform is a non-stock item & extended lead times are advised For all other Sika products on our website, please click here. f

-

£312.68 ex. VATSika Hyflex 250 Facade is a 1-component, moisture-curing, low-modulus elastic joint sealant. CHARACTERISTICS / ADVANTAGES - Excellent weathering resistance - Bubble-free curing - Low stress to the substrate - Perfect extrusion and workability - Excellent adhesion to many different substrates - Solvent-free - Very low emissions For a barrel gun, click here. For smaller cartridges, click here. For all our Sika products on our website, please click here. Any further information you may need on Sika / Everbuild products, please visit their website here.

-

£23.10 ex. VATBond It Geo-Fix All Weather is a single component joint filling system for the simple and rapid pointing of paved areas with joints over 5mm. Ready-to-use, simple brush application. Can be used in both dry and wet conditions ‐ no more wasted days due to wet weather. Features & Benefits: - Can be used in both dry and wet conditions ‐ no more wasted days due to wet weather - Can be used on joint widths of a minimum of 5 mm wide and a minimum of 15 mm deep. Semi‐rigid allowing for expansion and contraction of paving - GEO‐FIX All Weather is unaffected by w

-

£210.60 ex. VATSikaflex PRO-3 Purform Self Levelling is a one-part, moisture curing, self-levelling elastic joint sealant with high mechanical resistance for the following indoor and outdoor applications: Characteristics / Advantages ■ Movement capability of 25% (ISO 9047) ■ Bubble-free curing ■ Self-levelling ■ Excellent adhesion to most construction materials ■ Solvent-free and odourless ■ Very low emission Please note, PRO-3 Purform is a new formula introduced 2022 For all other Sika products on our website, please click here. For any further informati

-

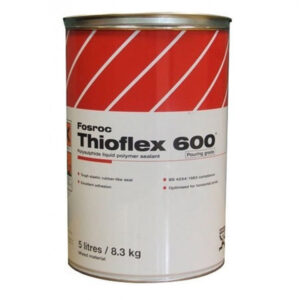

£93.21 ex. VATFOSROC Thioflex 600 Pour Grade is a multi-component, gun grade, polysulfide sealant, that comes in a tin that contains both the base and curing agent in the correct proportions. Advantages - Meets key international standards - Forms a robust, elastic, rubber-like seal - Accommodates continuous and pronounced cyclic movement Fosroc thioflex 600 pour grade comes in a 5litre tin. For all other FOSROC products on our website, please click here. For any further information you need on FOSROC products, please visit their website here.

-

£69.00 ex. VATCM200 PF Fast Cure is a two-part sealant that is used for several sealing areas. Most commonly used for sealing expansion joints, due to the advantages of the CM 200 PF is can be used for sealing expansion joints in concrete paved areas, docks, container depots, industrial factories, warehousing petrol forecourts. CM200 PF can be cold applied, so ideal for small works, such as remedial re-sealing of joints. Advantages High-performance good movement accommodation, tolerant of severe climatic conditions. Chemical Resistant to spillages of fuels, hydraulic fluids, synthetic

-

£27.30 ex. VATBond It Geo-Fix Original is a single component joint filling system for the simple and rapid pointing of paved areas with joints over 5mm. Ready-to-use, simple brush application. For use in dry conditions. Not compatible with porcelain tiles. Features & Benefits: - GEO‐FIX is unaffected by wind, rain washout and mechanical sweeping equipment - Can be used on joint widths of a minimum of 5 mm wide and a minimum of 25 mm deep. Semi‐rigid allowing for expansion and contraction of paving - No mixing required - Brush applied ‐ no special skills or

Floor Joints Sealants

Floor joint sealants are highly sought after, with many trade specialists searching for the best possible deals and discounts. At Sealant Supplies we take pride on being a reliable source for all things sealants, adhesives and accessories.

We stock brands ranging from CM Sealants, through to Fosroc and Sikaflex, to ensure we are able to provide a variety of price and product ranges for our customers. Our floor joint sealants are often purchased by trade professionals and so, we provide a range of discounts for both bulk and repeat orders.

Our wood floor sealants can also be purchased in conjunction with other related products. Whatever your requirements, our team are here to assist you. We also stock a range of flooring sealant accessories and tools which make sealant application easier and more precise.

Our team also regularly review our stocklist to ensure we are providing the latest sealants and accessories at the best possible prices for our customers. If you have any specific requirements or a large order to place, simply reach out to our team.

All of our products can be found and ordered via our website, however if you do have any questions do not hesitate to get in touch with our experienced team. Call our office on 01708 525 866 or email info@sealantsupplies.co.uk and we will be in touch as soon as possible.