- Suitable For: floor and wall grouting of all types of ceramic tiles

- Area of use: INT & EXT

- Time to full cure: 24 hours

- Volume: 5kg

- Container Type: bag

- Type: GROUT

- Colour: 11 colours

- Brand: Mapei

- Manufactuer: Mapei

- Box Size: 1

Keracolor FF is a high performance cementitious grout, polymer modified, for joints up to 6 mm.

TECHNICAL CHARACTERISTICS

Keracolor FF is a blend of cement, very fine-graded aggregates, special polymers, additives and pigments. The use of special hydrophobic additives (DropEffect and BioBlock technology) gives grouting mortars highly water-repellent properties, making them less prone to dirtiness and with excellent durability. The addition of BioBlock® technology resists the growth of mould and mildew, allowing the grout to be easily cleaned.

The following features are obtained when mixed with the right water ratio and used correctly:

– water-repellent and droplet-effect;

– mould and mildew resistant

– good compressive and flexural strength, good resistance to freeze/thaw cycles, and therefore good durability;

– a smooth final surface with low water absorption, therefore easy to clean;

– excellent abrasion resistance;

– low shrinkage, therefore an absence of cracks and fissures;

– good resistance to acids with pH >3;

– excellent value for performance.

When mixing Keracolor FF with Fugolastic, a special synthetic resin-based polymeric additive, the final characteristics are improved for use even under harsh conditions (grouting façades, swimming pools, bathrooms, floors with heavy traffic). For further information, consult the Fugolastic technical datasheet.

Please note, this is a non-stock item for us & extended lead times of around a week are advised

To calculate quantities, please use the Mapei grout calculator here

Matching silicone available here.

For more information on this product, visit the Mapei website here.

Grouting interior and exterior floor and wall tiling (single fired, double fired, klinker, porcelain tile, etc.), stone material (natural stones, marble, granite, agglomerates, etc.), glass and marble mosaics.

Some application examples;

– Grouting floor and ceramic wall tiles in interiors.

– Grouting swimming pools.

– Grouting particularly smooth and glossy floor surfaces (smooth and polished porcelain, pre-smoothened and polished marble, glazed tiles).

– Grouting ceramic tile industrial flooring where resistance to chemical agents is not required (garages, warehouses, etc.).

APPLICATION

Preparing the joints

Before grouting, wait until the installation mortar or the adhesive has completely hardened. Verify that the waiting time indicated on the relevant technical data sheet has elapsed. The joints must be clean, free of dust and raked back to at least 2/3 of the tile thickness. Excess adhesive or mortar should be removed whilst still fresh.

Wet the joints with clean water when using very porous ceramic tiles in high temperatures and in the presence of wind.

Preparing the mix

While stirring, pour Keracolor FF into a clean, rust-free container containing 26 – 28% by weight, dependant on grout colour, of clean water or Fugolastic (if required in the application). When grouting floors, the mixture can be made thinner by adding more water (approx. 27 – 30% by weight). Mix with a low speed mixer to avoid excess formation of air bubbles, to a smooth

consistency. Wait 2-3 minutes and briefly re-stir before use. Use the mixture within 2 hours of preparation.

Applying the grout

Fill the joints completely with Keracolor FF using the appropriate MAPEI trowel or rubber float, making sure the joints are completely compacted, with no unevenness. Remove excess Keracolor FF, while still fresh, from the surface moving the float diagonally across joints.

LIMITATIONS

– Do not mix Keracolor FF with cement or any other products. Never add water to the mixture that is beginning to set.

– Do not blend different grout colours together as there is a risk of colour inconsistency and lack of uniformity of the final shade once the grout has set.

– Never mix Keracolor FF with salty or dirty water.

– Use the product in temperatures between +5°C and +35°C.

4 reviews for Mapei Keracolor FF 5KG

You must be logged in to post a review.

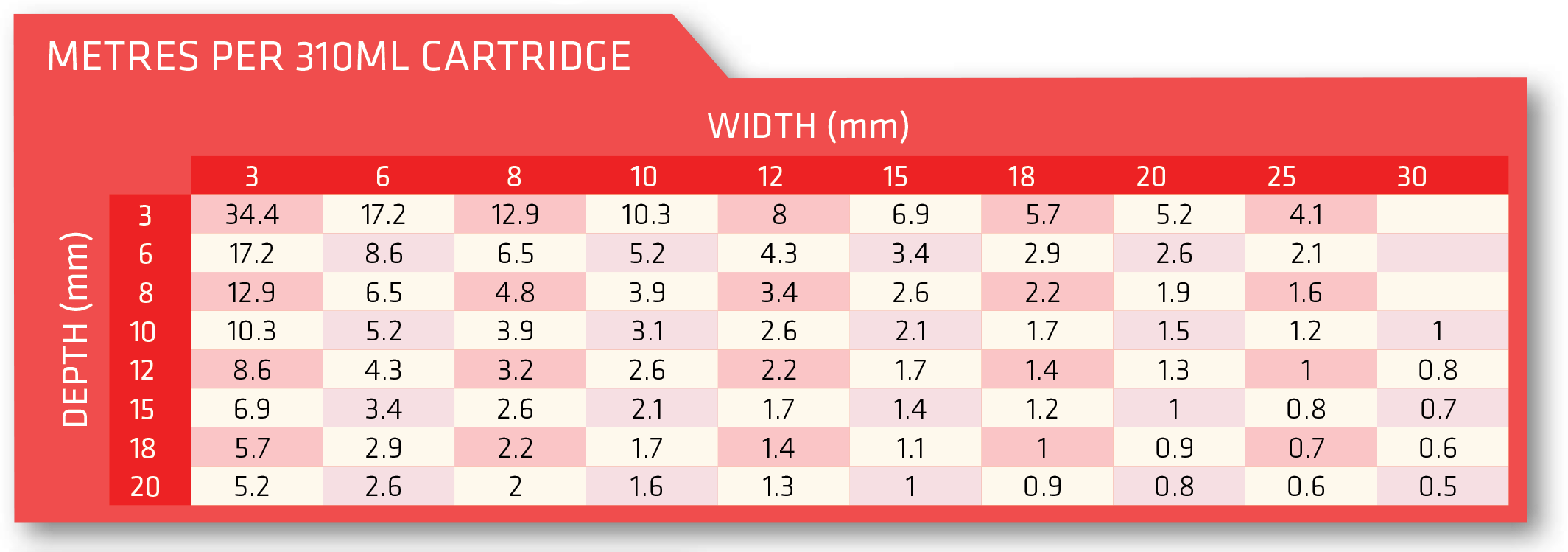

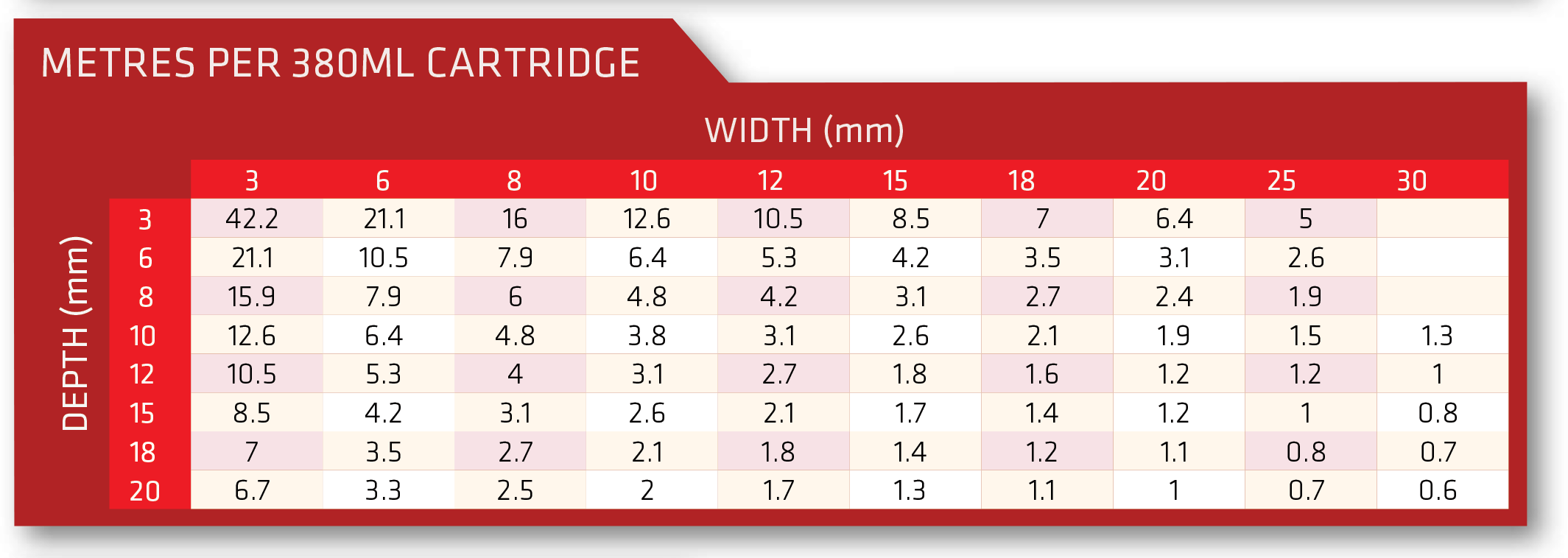

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

From: £8.03 inc. VAT

£6.69 ex. VAT

-

£3.24 inc. VAT

£2.70 ex. VATBond-It De-Bond Mate is A non-drip gel formula for the complete removal of cured silicone sealant, particularly when silicone has been accidentally smeared over glass, ceramics or countertops. Removes all types of silicone sealant, leaving surfaces ready for re-sealing. For all other Bond-it products on our website, please click here. For any further information, you may need on Bond-it, please visit their website here. -

£2.83 inc. VAT

£2.36 ex. VATBond-it Flash Mate Lead Silicone is a low modulus neutral cure fast-skinning, roof sealant It is a high-performance neutral cure silicone sealant, specifically designed for use with roofing products both modern and traditional. For all other Bond-it products on our website, please click here. For an alternative silicone for lead, click here. For any further information you may need on Bond-it, please visit their website here. -

£8.14£1.19 inc. VAT£6.78£0.99 ex. VAT£8.14£1.19 inc. VAT£6.78£0.99 ex. VATARBO Arbosil 1070 represents a single-component, Low Modulus Silicone Sealant with Fire-Resistant properties. It undergoes curing upon exposure to moisture vapor, ultimately transforming into a highly flexible silicone rubber material. For more information on Arbo, please visit their website here. For more in our range of sealants, please click here. For application guns to use with this product, please click here. -

£3.61£1.19 inc. VAT£3.01£0.99 ex. VAT£3.61£1.19 inc. VAT£3.01£0.99 ex. VATBond It LMH25 is a tough, flexible hybrid sealant ideal for installing internal and external window and door frames. Can also be used for sealing expansion and connection joints between most common substrates, without the use of a primer. PLEASE NOTE: THIS PRODUCT HAS A SHELF LIFE OF ONE MONTH BENEFITS - Solvent‐free & low odour. - Easy to tool and finish. - Can be overpainted with water based paints. - UV resistant. - Quick curing. - Contains no isocyanates, solvents, silicone and phthalates. - Excellent adhesion to most surfaces (even moist surf

Eileen B. (verified owner) –

Great communication re delivery

WILLIAM JOHNSON (verified owner) –

Anonymous (verified owner) –

Pam B. (verified owner) –

Great product